Rotor Electronic Drive System

Guide Wheel Design Using

An Internal Spoke Wheel.

Inductive Braking.

Guide Wheel Design Using

An Internal Spoke Wheel.

Inductive Braking.

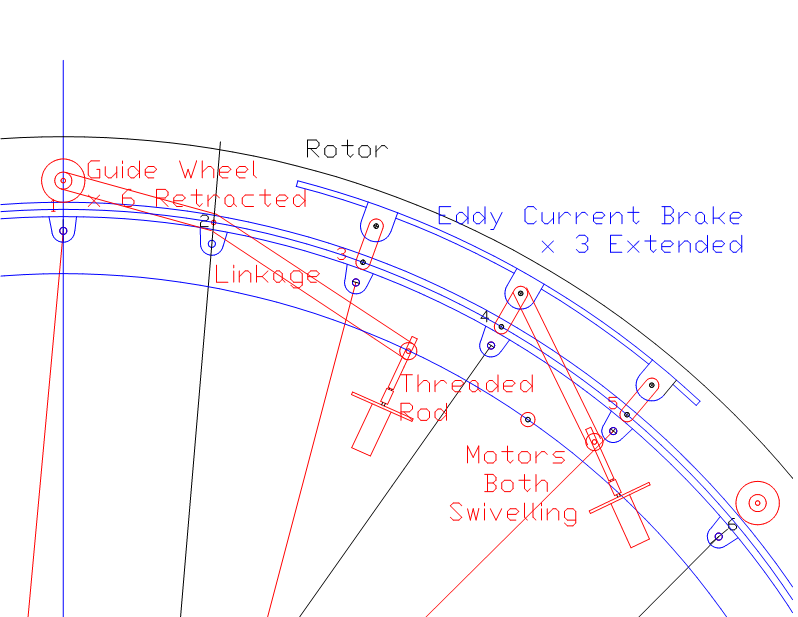

The use of Inductive Braking on this Machine is a variation on the normal application. I would normally require that the Rotor be slowed over a long period of time. The use here is to bring the Rotor to a controlled stop from Idle Speed. At Idle Speed the Spoke Wheel or Slew Ring would be stationary. To stop the Rotor, the first step would be to extend some aluminium plates from the Spoke Wheel or Slew Ring to a position inside the magnetic fields of the drive magnets. Full power would then be applied to the Rotor to keep it at Idle Speed. The Inductive Braking should then bring the Spoke Wheel or Slew Ring up to a speed close to that of the Rotor. The Guide Wheels would then be extended, and once in their correct position the power to the Rotor would be switched off.

As the spoke wheel is requiring more power than anticipated to achieve the required speed I will add motorization to the spoke wheel instead of the inductive braking.