Machine Rotor Construction

More Rotor Radial Levitation Magnets

More Rotor Radial Levitation Magnets

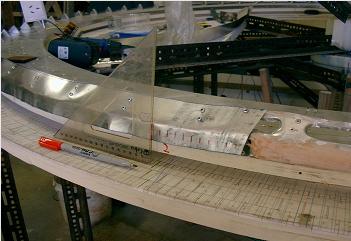

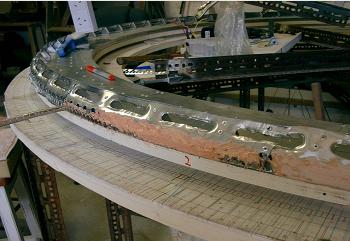

Top left Marking magnet positions from drawing.

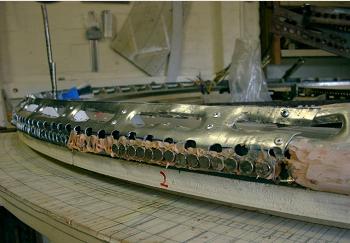

Top right Magnets bedded in epoxy.(Car Filler)

Bottom left Magnets in a stick. Slide across to next hole.

Bottom right More epoxy added a bit at a time.

Top right Magnets bedded in epoxy.(Car Filler)

Bottom left Magnets in a stick. Slide across to next hole.

Bottom right More epoxy added a bit at a time.

The magnets are held in place with magnetic attraction and epoxy to a steel backing behind an aluminum locating panel which is secured with many Pop rivets. The 25mm steel backing strip is held with 2 countersunk head S/Steel Pop rivets every 50mm directly into the integral flange of the rotor skin. Also many holes are drilled into the rotor for the epoxy to obtain maximum grip. The centrifugal force on these outer magnets is likely to be substantial, but there is also a huge counter balancing effect from the frame opposing magnets, so hopefully the rotor will be reasonably safe.