Machine Frame or Stator

Retractable Guide Wheels

Retractable Guide Wheels

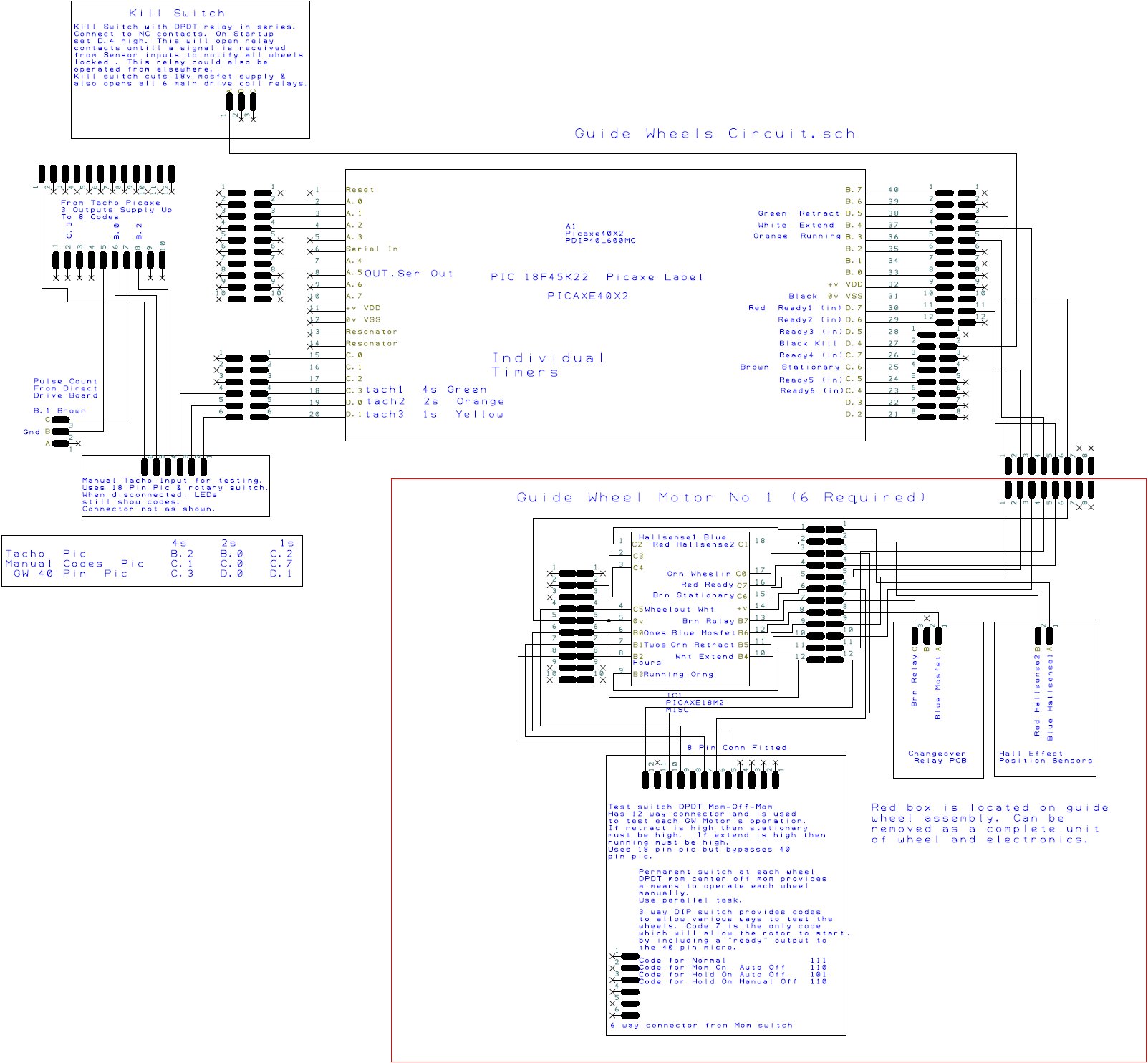

As it may be impossible to achieve stable static magnetic levitation of the rotor, a series of 6 roller blade wheels (75mm diameter) have been fitted around the stator or frame. These hold the rotor loosely (3mm play) in position until a speed is reached where the rotor should attain stable dynamic rotation.The wheels run on the drive magnets. Each one is fitted on a lever arm which allows for the wheel to be retracted a further 10mm from the rotor. I tried to operate the guide wheels with electro magnets, but while this seemed to be the easiest and cheapest option, it proved too difficult for me, and I have now converted to using six small 12v geared motors, 160 RPM, all operating in unison. This should be a better arrangement, as each wheel is held solidly against rotor bounce as its position is changing. The original wheel unit has been retained, but now has another lever arm fitted at a right angle, with the motor driving this via a threaded rod.(M10). The time taken to complete the wheel travel is about 20 seconds, and very little current is drawn,(400mA). Each wheel now has its own Picaxe micro to control the switching and reversing of the wheel. If the wheels require a longer time for retraction this can be done by switching the wheel motor off and on, and/or controlling the voltage via PWM. The programming for each wheel is identical, with a master micro to coordinate between the tacho and the guide wheels. Two Hall Effect switches are fitted to each wheel unit, one for fully extended and the other for fully retracted, and the output from these determines which direction the motor will run. Two safety micro switches are fitted just past the travel of the Hall Effect magnets. These switches carry the motor current, so will stop the motor if the electronics fail. A DIP switch is fitted to each wheel, to allow a wheel to be individually tested, both manually or automatically. Another rotary switch and picaxe is fitted between the tacho and control pic. This enables testing of all guide wheels in unison with the rotor locked in the stationary position.

As at July 2014 all wheels have been tested for operation with the rotor locked, and all seem to work as expected. However, when the rotor is powered up, all six guide wheels are retracting spontaneously at a rotor speed of only about 1mps. This has now been resolved by insulating all coils from the machine stator or frame as large BEMF spikes were interfering with the micro operation.

As at July 2014 all wheels have been tested for operation with the rotor locked, and all seem to work as expected. However, when the rotor is powered up, all six guide wheels are retracting spontaneously at a rotor speed of only about 1mps. This has now been resolved by insulating all coils from the machine stator or frame as large BEMF spikes were interfering with the micro operation.

This circuit is constantly changing and may not be up to date, but it is a general indication of the way the guide wheels are wired.