Rotor Electronic Drive System

Test & Measuring Equipment

Scales

Test & Measuring Equipment

Scales

Machine Weighing.

The machine weight needs to be known and monitored easily to see if there is any change when rotating, and this needs to be done from a safe distance.

The machine was sitting on 3 older style analogue dial type bathroom scales and weighed in at 217 kg. The rotor weighs about 30 of those kg. I have made some changes to the machine, and as of Dec 2016 the Machine now sits on 7 of these old scales to spread the load more evenly. Only 3 have been converted for electronic use, so the reading will now be 3/7 of the approximate weight.

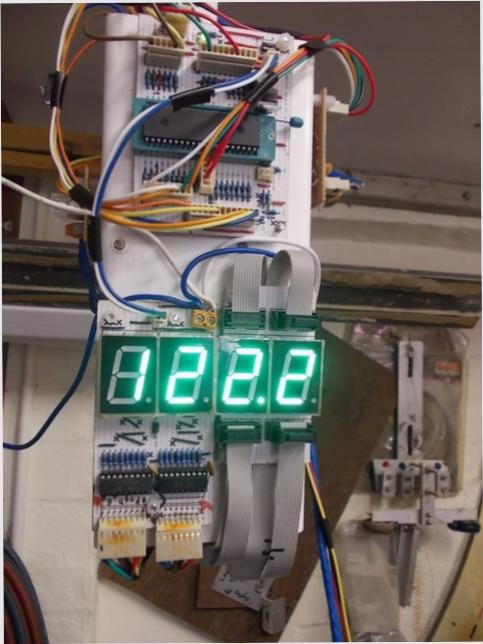

As it seems to be very dangerous to attempt to read these scales with the Rotor spinning, I have made a 4 digit display using 1" 7 segment LEDs similar to the tacho, but this can read to 999.9 kg. The bathroom scales will go to a max of 120kg each for a total of 840kg. Three scales have been fitted with a magnet and a Hall Effect sensor. The system is quite sensitive but may lack accuracy. Adjustment has been made in the program and the LED display was accurate at the current weight, before changing to 7 scales. The weight reading

shown below, 122.2Kg, is 3/7 of the weight. So the true weight now is about 284Kg.

A 40 pin Picaxe 40X2 has been used, as this allows for another 4 digit display to be connected to the same Pic. The Pic collects the data from the 3 scales and sums this for the LED display output. The PCBs are Veroboard. One board for 2 digits. These connect together reasonable easily. The design is for common cathode displays, but should be ok for common anode with minor changes and a different Darlington driver. A 4081 AND gate is included on each PCB. This gives the ability to control the display intensity via PWM and allows for moving decimal points or more digit blanking if required. This system has been built and tested OK. I intend to use the expansion capability to include an ammeter. Provision has been included for I2C data transfer if required. This system would be ideal for twin tachos, or highly visible volt and ammeter displays to check the motor electrical consumption.

The machine weight needs to be known and monitored easily to see if there is any change when rotating, and this needs to be done from a safe distance.

The machine was sitting on 3 older style analogue dial type bathroom scales and weighed in at 217 kg. The rotor weighs about 30 of those kg. I have made some changes to the machine, and as of Dec 2016 the Machine now sits on 7 of these old scales to spread the load more evenly. Only 3 have been converted for electronic use, so the reading will now be 3/7 of the approximate weight.

As it seems to be very dangerous to attempt to read these scales with the Rotor spinning, I have made a 4 digit display using 1" 7 segment LEDs similar to the tacho, but this can read to 999.9 kg. The bathroom scales will go to a max of 120kg each for a total of 840kg. Three scales have been fitted with a magnet and a Hall Effect sensor. The system is quite sensitive but may lack accuracy. Adjustment has been made in the program and the LED display was accurate at the current weight, before changing to 7 scales. The weight reading

shown below, 122.2Kg, is 3/7 of the weight. So the true weight now is about 284Kg.

A 40 pin Picaxe 40X2 has been used, as this allows for another 4 digit display to be connected to the same Pic. The Pic collects the data from the 3 scales and sums this for the LED display output. The PCBs are Veroboard. One board for 2 digits. These connect together reasonable easily. The design is for common cathode displays, but should be ok for common anode with minor changes and a different Darlington driver. A 4081 AND gate is included on each PCB. This gives the ability to control the display intensity via PWM and allows for moving decimal points or more digit blanking if required. This system has been built and tested OK. I intend to use the expansion capability to include an ammeter. Provision has been included for I2C data transfer if required. This system would be ideal for twin tachos, or highly visible volt and ammeter displays to check the motor electrical consumption.